The digital workflow improved my smile as well.

-Dr. Beat R. Kurt

With today’s advanced implant technology enabling a much more digital workflow, my team and I can now help our patients achieve more effective restorations in a quicker, more comfortable manner. As a recent example, a 77-year-old healthy male was referred to my practice for an implant rehabilitation of the maxillary left anterior region. He was recently in an accident and fractured the two pillars of the existing bridge, 21 x 23. As a result, both teeth were not viable for fabrication of a new conventional bridge.

Diagnostic records and prework.

After acquiring the initial photos and radiographs, we captured a digital impression using the CS 3600 intraoral scanner from Carestream Dental. We also acquired a pre-operative CBCT scan. Both of these files — the CBCT and digital impression — were then sent to the dental lab technician for design. The technician imported the files into exocad software and designed a wax-up for the new implant bridge for teeth 21i x 23i. Next, the DICOM data, a modified model (where the fractured roots of 21 and 23 were virtually extracted in Meshmixer software), the opposing arch model and the new wax-up from the lab technician were imported into the SMOP implant planning software from Swissmeda.

Now the implants could be optimally planned to achieve the goal of immediate implantation and placement of a direct screw-retained bridge on teeth 21i x 23i. Two Straumann BLT RC 4.1 mm, 12 mm implants were planned in regions 21 and 23. With a new import of the data into exocad, the lab technician milled a PMMA provisional bridge. The provisional bridge fit was verified using a control model printed by Dreve 3D model printing services. Two temporary cylindrical abutments were modified with Opaquer. Meanwhile, the surgical guide was designed in SMOP and then printed with a Stratasys 260 printer using medically approved M 610 material. The surgical guide fit was also verified using the Dreve control model.

Surgery.

The two fractured teeth — 21 and 23 — were removed under local anesthesia, and a Straumann-guided surgery kit was used to perform the osteotomy of the implants. Two Straumann BLT RC SLActive 4.1 mm, 12 mm implants were placed using a surgical guide. Both ISQ values were above 65. Next, the provisional PMMA bridge was cemented onto the two temporary cylindrical abutments. The bone defects were filled with Bio-Oss and covered with a double layer of Bio-Gide, both materials from Geistlich. The occlusal contacts of the bridge were adjusted to improve the overall occlusion and contact pattern of the patient’s teeth. The patient was prescribed amoxicillin and clavulanic acid for seven days postoperative as infection prophylaxis, and ibuprofen as a painkiller. Additionally, chlorhexidin 0.2 % was prescribed as an oral rinse.

Follow-up.

Suture removal was performed at the first control appointment, one week post-surgery. After three months, the referring dentist placed the final screw-retained full zirconia bridge. The final control radiographs and the post-healing photographs were completed in my practice, with a satisfactory final outcome and a very happy patient.

Benefits of a digital workflow.

I have found that using digital technology offers a number of advantages for both my patients and my practice. For example, capturing an impression digitally saves time by reducing errors in the impression acquisition as well as eliminating the need for a stone model pour-up. And because the CS 3600 intraoral scanner produces open digital files, those files can be easily sent to the lab via digital file transfer for faster fabrication and improved communication.

This particular case was awarded the Best Digital Implant Case at the 2018 Digital Dental Academy Awards, but more importantly, it resulted in one very happy, smiling patient. Of course, such a case requires two very important things to be successful: First, you need a talented and experienced team. In this case, that team included my practice staff, my dental technician, Andreas Schwab, Baar and my referring general dentist, Dr. Reto Sütterlin. Second, you need the latest tools and technology that allow for quick, efficient and comfortable procedures.

A great team plus great technology equals a great outcome. And that’s the story behind this smile.

Initial situation showing fractured pillars 21 and 23

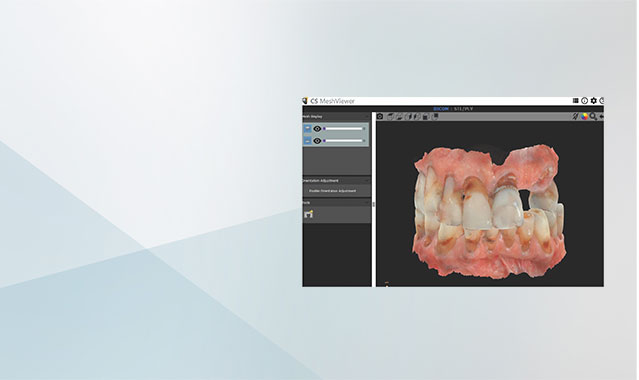

Reviewing the digital impression in CS MeshViewer software

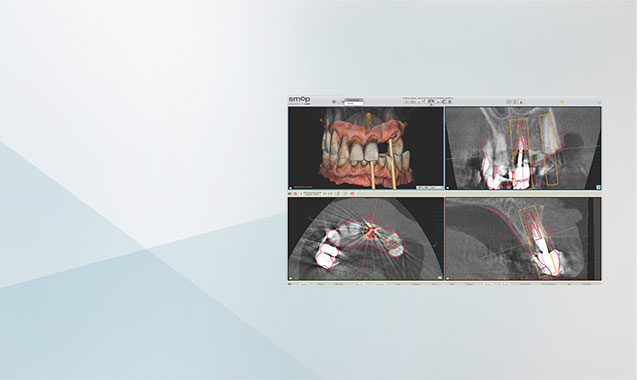

Viewing the digital impression and wax-up in SMOP implant planning software

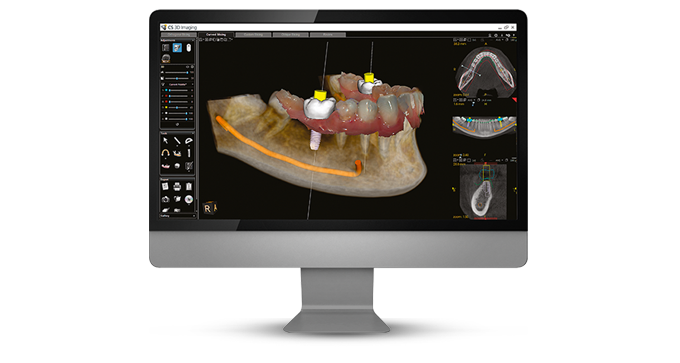

Initial implant placement in SMOP implant planning software with merged CBCT and digital impression datasets

Virtual model of the surgical guide and implant placement

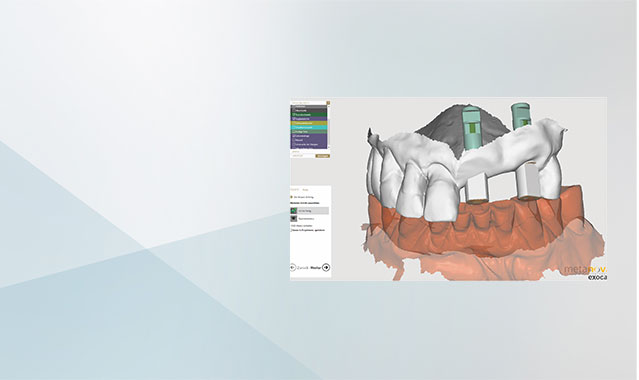

Import of the STL data of the scan body, model and wax-up in exocad

Fully digitally designed provisional bridge on control model

Final intraoral photograph

This module allows you to combine CBCT and digital impression data and add virtual crowns and implants to create a more comprehensive treatment plan.

Known for its fast, accurate and easy digital impression capture, the CS 3600 provides improved treatment planning and a streamlined workflow.

|

What can we do to make you smile?

|

|

|

Need some product information? Want a free workflow assessment? Connect with us and we will give you what you need. |

|

Simple Form for Landing Pages - US/Canada

|

*Indicates required field

Review the Carestream Dental Privacy Shield Policy HERE.Opens in new window

|