Prosthetic-Driven Implant Planning CLINICAL CASE: Anterior Single Implant-supported Restoration in the Aesthetic Zone Using Guided Surgery

by Dr. Nicolas Boutin

A 35-year old male patient presented at the office with a missing maxillary lateral incisor. Visual examination revealed limited space for the restoration as well as a supraclusion.

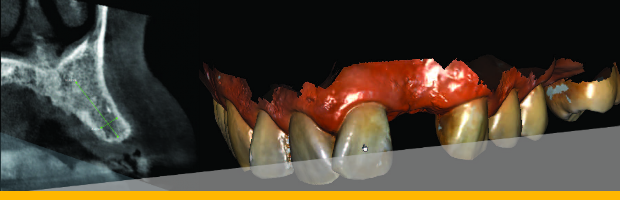

A cone beam computed tomography (CBCT) scan was taken to validate the bone volume. The implant was planned in the CS 3D Imaging software using a virtual tooth to determine if the prosthetic emergence would be compatible with the underlying bone volume. When the feasibility of the treatment was validated, digital impressions were acquired using the CS 3600 intraoral scanner. The impression file was sent to the dental laboratory to create a wax up, which was then used to generate a second digital model. Using NobelClinicianTM software, this file was merged with the patient’s CBCT scan to complete implant planning and create and order a surgical guide.

Treatment plan

The surgery was performed using a pilot drill guide to position the axis of implants and was then completed free-hand. The digital impression was taken with the CS 3600 intraoral scanner, which allowed the implant network to quickly create the temporary restoration for immediate loading. Once the digital impression was transferred to the laboratory, the restoration design was validated live through an online video conference before milling took place. Less than two hours later, the patient received the temporary crown.

Testimonial

On an aesthetic zone with limited space between teeth, the prosthetic-driven planning enabled us to determine accurately the implant axis in order to place the screw-retained implant in a more palatal position. With CBCT imaging and 3D implant planning software, we were able to effortlessly plan and validate this case. By combining implant planning with guided surgery, we achieved a successful prosthetic outcome. Digital impression complements the digital workflow with the capability to immediately place the temporary restoration—thanks to CAD/CAM design and milling.